NiAl cladding poda ine simba rekubatanidza rakasimba

Tsanangudzo

Isu tinodada kuunza zvigadzirwa zviviri zvinoenderana neNiAl hupfu: KF-2 uye KF-6.Izvi zvigadzirwa zviviri zvinoshandisa mareshiyo akasiyana eNiAl poda uye ane akasiyana hunhu uye mashandisiro.

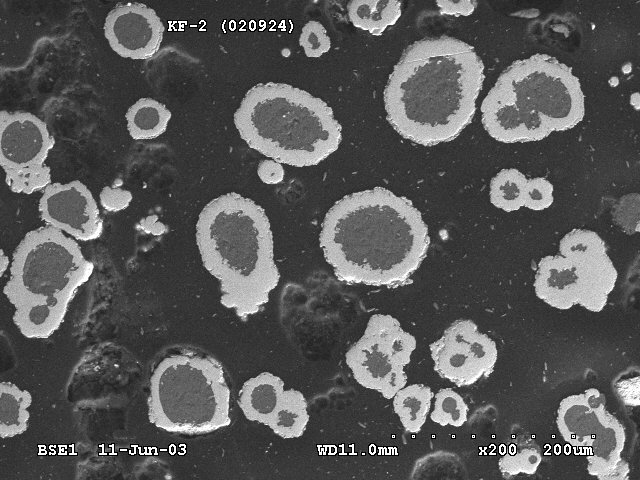

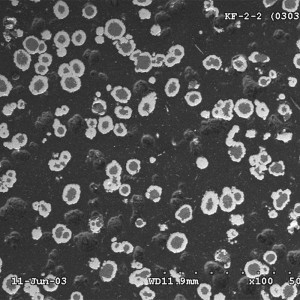

KF-2 inoshandisa NiAl82/18, iyo ine 82% Ni uye 18% Al.Ichi chigadzirwa chakakodzera kushandiswa nepamusoro pekushanda tembiricha ye650°C.Inopa dense, machinable, oxidation-resistant, uye kupfeka-inodzivirira coating ine self-bonding zvivakwa.Iko kunogara kuine exothermic kuita panguva yekupfapfaidza, izvo zvinoguma nekusimba kwekubatana kwepamusoro kune Ni5Al zvinhu.KF-2 inokodzera kugadzirisa uye kugadzirazve machinable kabhoni simbi uye isingaore simbi, uye inogona zvakare kushandiswa pakubatanidza zvidimbu zveceramic uye zvinopfekwa.

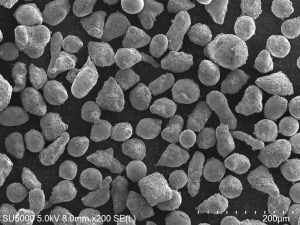

KF-6 inoshandisa NiAl95/5, iyo ine 95% Ni uye 5% Al.Ichi chigadzirwa chinokodzera kushandiswa nekushisa kwepamusoro kwe800 ° C uye chinogona kushandiswa uchishandisa nzira dzakasiyana-siyana dzekupfapfaidza dzakadai seflame, APS, neHVOF.Inopawo dense, machinable, oxidation-resistant, uye kupfeka-inodzivirira coating ine self-bonding zvivakwa.Iko kunogara kune exothermic reaction panguva yekupfapfaidza, zvichikonzera kusimba kwekubatana.KF-6 inogona zvakare kushandiswa kugadzirisa uye kugadzira zvakare machinable kabhoni simbi uye isingaore simbi, pamwe nekubatanidza zvidimbu zveceramic uye zvinopfekwa.

Muchidimbu, zvese KF-2 uye KF-6 iNiAl poda-yakavakirwa zvigadzirwa zvinopa yakanakisa kubatanidza simba uye kupfeka kuramba.KF-2, ine yakaderera muzana yeNiAl hupfu (NiAl82/18), inokodzera zvikumbiro zvine tembiricha yekushanda ye650 ° C, nepo KF-6, ine chikamu chepamusoro cheNiAl powder (NiAl95/5), inogona kubata tembiricha yepamusoro kusvika 800°C uye inogona kuiswa uchishandisa nzira dzakasiyana dzekupfapfaidza.Zvigadzirwa zvese zviri zviviri zvakanakira kugadzirisa nekugadzirazve machinable kabhoni simbi uye isingaore simbi, pamwe nekubatanidza zvidimbu zveceramic uye zvinopfekwa.Sarudzo pakati peKF-2 neKF-6 zvinoenderana nezvinodiwa zvekushandisa uye tembiricha yekushanda inodiwa.

Zvigadzirwa zvakafanana

| Brand | Product Name | AMPERIT | METCO/AMDRY | WOKA | PRAXAIR | PAC |

| KF-2 | NiAl82/18 | 404NS | ||||

| KF-6 | NiAl95/5 | 282 | 956450NS | NI-109 | 906 |

Tsanangudzo

| Brand | Product Name | Chemistry (wt%) | Kuoma | Tembiricha | Properties & Application | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Al | W | Mo | Cr | Al2O3 | MoS2 | WC | C | Fe | Ni | |||||

| KF-2 | NiAl82/18 | 20 | Bal. | HRC 20 | ≤ 800ºC | •Murazvo, APS, Max.kushanda tembiricha 650°C. • Dense uye machinable oxidation inoshingirira uye kupfeka inodzivirira coating. | ||||||||

| KF-6 | NiAl95/5 | 5 | Bal. | HRC 20 | ≤ 800ºC | •Flame, APS, HVOF, Max.kushanda tembiricha 800°C • Dense uye machinable oxidation inoshingirira uye kupfeka inodzivirira coating | ||||||||

| KF-20 | Ni-MoS₂ | 22 | Bal. | HRC 20 | ≤ 500ºC | •Inoshandiswa pakuisa chisimbiso zvikamu uye zvindori zvinogayiwa •Inogona kushandiswa seyakaderera friction material | ||||||||

| KF-21T | Ni-Graphite 75/25 | 25 | Bal. | HRC 20 | ≤ 480ºC | •Murazvo, Max.kushanda tembiricha 480 ° C 1. Kupfeka zvinhu zve turbo compressor •Inoshanda kune nickel alloy uye zvikamu zvesimbi • Zvigadzirwa zvine girafu yepamusoro zvakakodzerwa netitanium zvikamu zvisina mupendero • High graphite content ichawedzera lubrication performance •Yakakwirira nickel yemukati inovandudza kusakukurwa kwevhu • Zvigadzirwa zvakafanana zvakasiyana nekuda kwekusiyana kweOEM | ||||||||

| KF-22T/R | Ni-Graphite 60/40 | 50 | Bal. | HRC 20 | ≤ 480ºC | |||||||||

| KF-21R | Ni-Graphite 75/25 | 25 | Bal. | HRC 20 | ≤ 480ºC | |||||||||

| KF-45 | Ni-Al2O3 77/23 | 23 | Bal. | HRC 40 | ≤ 800ºC | •Flame,APS, isingaite • Inogona kushandiswa kunyungudutsa crucible, terminal sealing surface uye mold pamusoro seyekudzivirira layer | ||||||||

| KF-56 | Ni-WC 16/84 | Bal. | 12 | HRC 62 | ≤ 400ºC | •Flame,APS, isingaite •Kusada kurohwa nesando, kukukurwa, kukwenya uye kutsemuka | ||||||||

| KF-50 | Ni-WC10/90 | Bal. | 10 | HRC 62 | ≤ 400ºC | •Murazvo, zvisina kujairika •Kusada kurohwa nesando, kukukurwa, kukwenya uye kutsemuka | ||||||||

| KF-91Fe | Fe-WC | 4 | 27 | 9.5 | Bal. | 5.5 | HRC 40 | ≤ 550ºC | •Flame, APS, zvisingaite, Max.tembiricha yekushandisa 815°C. •Pfeka mabatiro asingachinjike, ayo anogona kushandiswa kugadzirisa matangi mabhureki | |||||

| KF-110 | NiCr-Al 95/5 | 5 | 7.5 | Bal. | HRC 20 | ≤ 800ºC | •Murazvo, APS, Max.kushanda tembiricha 980°C. •Plasma spraying with self bonding | |||||||

| KF-113A | NiCrAl-CoY2O3 | Cr+Al:20, Ni+Co:75 | HRC 20 | ≤ 900ºC | •APS,HVOF, zvisingaite, Max.kushanda tembiricha 980°C. •Inoshanda pakugadziriswa kwepamusoro tembiricha bonding layer kana kupfeka / zvisina kurongeka zvikamu | |||||||||

| KF-133 | NiMoAl | 5 | 5 | Bal. | HRC 20 | ≤ 650ºC | •Self bonding, yakajairika hard coating yekutakura application •Zvakaoma, zvine ngura yakanaka kuramba uye nekukanganisa kuita •Inoshandiswa kune zvikamu zvemuchina, chigaro chekutakura uye valve | |||||||

| KF-31 | Ni-Diatomite 75/25 | •Flame,APS, zvisingaite, Max.kushanda tembiricha 650°C. •Pakuyeya chisimbiso chinobatika, zvinosanganisira zvinofambiswa zvisimbiso, grindable seal rings, low friction materials. | ||||||||||||