Ni-Graphite Cladding poda ine magetsi conductivity

Tsanangudzo

Ni-Graphite Cladding poda chinhu chakanyanya hunyanzvi chakagadzirwa kuti chipe hunyanzvi hwekuita mukudiwa kwemaindasitiri.Iyi hupfu hutsva hwakapfekwa nekemikari nehuwandu hwenickel uye graphite, zvichiita kuti ive sarudzo yakanaka yekushandisa mukupfeka zvinhu zveturbo compressors, nickel alloy, uye zvikamu zvesimbi.

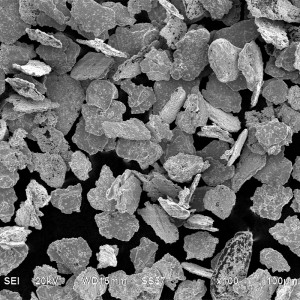

Chimwe chezvinhu zvakakosha zveNi-Graphite Cladding poda ndeye yakakwira graphite yemukati.Uhu hunhu hunosimudzira kuita kwekuzora kwehupfu, zvichiita kuti ive sarudzo yakakurumbira yekushandisa muzvikamu zvetitanium zvisina mupendero.Pamusoro pezvo, iyo yakakwira nickel yehupfu inonatsiridza kusakura kwayo kwekukukurwa, kuve nechokwadi kuti inopa kushanda kwakakwana munzvimbo dzakaoma dzeindasitiri.

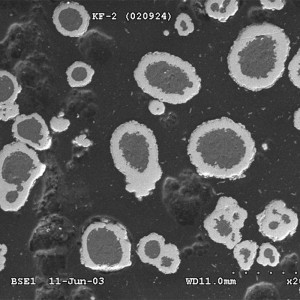

Ni-Graphite Cladding powder inowanikwa mumhando mbiri dzakasiyana: KF-21 Ni-Graphite 75/25 uye KF-22 Ni-Graphite 60/40.Aya maumbirwo maviri ane nickel akasiyana uye graphite zvemukati reshiyo, zvichiita kuti aenderane nemhando dzakasiyana dzemaindasitiri ekushandisa.Semuyenzaniso, KF-21 Ni-Graphite 75/25 ine nickel yakakwira zvirimo, zvichiita kuti ive yakanakira kushandiswa mumaapplication anoda epamusoro kusakura kwekukukurwa.

Pamusoro pekuita kwayo kwepamusoro-maitiro, Ni-Graphite Cladding poda zvakare inosiyana-siyana.Inogona kushandiswa mumhando dzakasiyana dzemaindasitiri ekushandisa, kusanganisira turbo compressors, nickel alloy, uye simbi zvikamu.Uyezve, kuramba kwayo murazvo uye tembiricha yekushanda ye480 ° C inoita kuti ive sarudzo yakavimbika yekushandisa mukupisa kwepamusoro.

Kana zvasvika pakusarudza iyo chaiyo Ni-Graphite Cladding poda yechishandiso chako cheindasitiri, zvakakosha kuti utarise iyo chaiyo OEM maratidziro emidziyo yako.KF-21 yakafanana ne AMPERIT 205, METCO/AMDRY 307NS, PRAXAIR NI-114, uye PAC 138, nepo KF-22 yakafanana ne AMPERIT 200 uye Durabrade 2211.

Mukupedzisa, Ni-Graphite Cladding poda chinhu chakanyanya hunyanzvi chinopa kuita kwepamusoro mukuda maindasitiri ekushandisa.Yayo yakakwira graphite yemukati uye yakakwira nickel yemukati inoita kuti ive sarudzo yakanaka yekushandisa mukupfeka zvinhu zveturbo compressors, nickel alloy, uye zvikamu zvesimbi.Nekuita kwayo kwakasiyana-siyana, kuramba kwemurazvo, uye kupisa kwakanyanya kwekushanda, Ni-Graphite Cladding poda isarudzo yakavimbika kune dzakasiyana siyana dzekushandisa mumaindasitiri.

Zvigadzirwa zvakafanana

| Brand | Product Name | AMPERIT | METCO/AMDRY | WOKA | PRAXAIR | PAC |

| KF-21T/R | Ni-Graphite 75/25 | 205 | 307NS | NI-114 | 138 | |

| KF-22T/R | Ni-Graphite 60/40 | 200 | Durabrade 2211 |

Tsanangudzo

| Brand | Product Name | Chemistry (wt%) | Kuoma | Tembiricha | Properties & Application | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Al | W | Mo | Cr | Al2O3 | MoS2 | WC | C | Fe | Ni | |||||

| KF-2 | NiAl82/18 | 20 | Bal. | HRC 20 | ≤ 800ºC | •Murazvo, APS, Max.kushanda tembiricha 650°C. • Dense uye machinable oxidation inoshingirira uye kupfeka inodzivirira coating. | ||||||||

| KF-6 | NiAl95/5 | 5 | Bal. | HRC 20 | ≤ 800ºC | •Flame, APS, HVOF, Max.kushanda tembiricha 800°C • Dense uye machinable oxidation inoshingirira uye kupfeka inodzivirira coating | ||||||||

| KF-20 | Ni-MoS₂ | 22 | Bal. | HRC 20 | ≤ 500ºC | •Inoshandiswa pakuisa chisimbiso zvikamu uye zvindori zvinogayiwa •Inogona kushandiswa seyakaderera friction material | ||||||||

| KF-21T | Ni-Graphite 75/25 | 25 | Bal. | HRC 20 | ≤ 480ºC | •Murazvo, Max.kushanda tembiricha 480 ° C 1. Kupfeka zvinhu zve turbo compressor •Inoshanda kune nickel alloy uye zvikamu zvesimbi • Zvigadzirwa zvine girafu yepamusoro zvakakodzerwa netitanium zvikamu zvisina mupendero • High graphite content ichawedzera lubrication performance •Yakakwirira nickel yemukati inovandudza kusakukurwa kwevhu • Zvigadzirwa zvakafanana zvakasiyana nekuda kwekusiyana kweOEM | ||||||||

| KF-22T/R | Ni-Graphite 60/40 | 50 | Bal. | HRC 20 | ≤ 480ºC | |||||||||

| KF-21R | Ni-Graphite 75/25 | 25 | Bal. | HRC 20 | ≤ 480ºC | |||||||||

| KF-45 | Ni-Al2O3 77/23 | 23 | Bal. | HRC 40 | ≤ 800ºC | •Flame,APS, isingaite • Inogona kushandiswa kunyungudutsa crucible, terminal sealing surface uye mold pamusoro seyekudzivirira layer | ||||||||

| KF-56 | Ni-WC 16/84 | Bal. | 12 | HRC 62 | ≤ 400ºC | •Flame,APS, isingaite •Kusada kurohwa nesando, kukukurwa, kukwenya uye kutsemuka | ||||||||

| KF-50 | Ni-WC10/90 | Bal. | 10 | HRC 62 | ≤ 400ºC | •Murazvo, zvisina kujairika •Kusada kurohwa nesando, kukukurwa, kukwenya uye kutsemuka | ||||||||

| KF-91Fe | Fe-WC | 4 | 27 | 9.5 | Bal. | 5.5 | HRC 40 | ≤ 550ºC | •Flame, APS, zvisingaite, Max.tembiricha yekushandisa 815°C. •Pfeka mabatiro asingachinjike, ayo anogona kushandiswa kugadzirisa matangi mabhureki | |||||

| KF-110 | NiCr-Al 95/5 | 5 | 7.5 | Bal. | HRC 20 | ≤ 800ºC | •Murazvo, APS, Max.kushanda tembiricha 980°C. •Plasma spraying with self bonding | |||||||

| KF-113A | NiCrAl-CoY2O3 | Cr+Al:20, Ni+Co:75 | HRC 20 | ≤ 900ºC | •APS,HVOF, zvisingaite, Max.kushanda tembiricha 980°C. •Inoshanda pakugadziriswa kwepamusoro tembiricha bonding layer kana kupfeka / zvisina kurongeka zvikamu | |||||||||

| KF-133 | NiMoAl | 5 | 5 | Bal. | HRC 20 | ≤ 650ºC | •Self bonding, yakajairika hard coating yekutakura application •Zvakaoma, zvine ngura yakanaka kuramba uye nekukanganisa kuita •Inoshandiswa kune zvikamu zvemuchina, chigaro chekutakura uye valve | |||||||

| KF-31 | Ni-Diatomite 75/25 | •Flame,APS, zvisingaite, Max.kushanda tembiricha 650°C. •Pakuyeya chisimbiso chinobatika, zvinosanganisira zvinofambiswa zvisimbiso, grindable seal rings, low friction materials. | ||||||||||||