Multi-function Composite cladding poda

Tsanangudzo

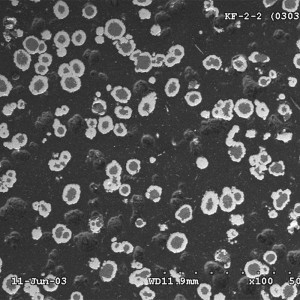

Nickel yakavharidzirwa graphite composite poda ivhu rakaumbwa rine graphite particles semusimboti wayo uye nickel yesimbi seyayo yekunze, ine mafuta ekuzora uye kusagadzikana kwekuora.Mushure mekupfapfaidza kwemafuta, zvinhu zvacho zvinogona kuumba simba rakawanda, oxidation kuramba, kupisa kwekushomeka kwekupokana uye yakaderera friction coefficient.

Tsanangudzo

| Brand | Product Name | Chemistry (wt%) | Kuoma | Tembiricha | Properties & Application | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Al | W | Mo | Cr | Al2O3 | MoS2 | WC | C | Fe | Ni | |||||

| KF-2 | NiAl82/18 | 20 | Bal. | HRC 20 | ≤ 800ºC | •Murazvo, APS, Max.kushanda tembiricha 650°C. • Dense uye machinable oxidation inoshingirira uye kupfeka inodzivirira coating. | ||||||||

| KF-6 | NiAl95/5 | 5 | Bal. | HRC 20 | ≤ 800ºC | •Flame, APS, HVOF, Max.kushanda tembiricha 800°C • Dense uye machinable oxidation inoshingirira uye kupfeka inodzivirira coating | ||||||||

| KF-20 | Ni-MoS₂ | 22 | Bal. | HRC 20 | ≤ 500ºC | •Inoshandiswa pakuisa chisimbiso zvikamu uye zvindori zvinogayiwa •Inogona kushandiswa seyakaderera friction material | ||||||||

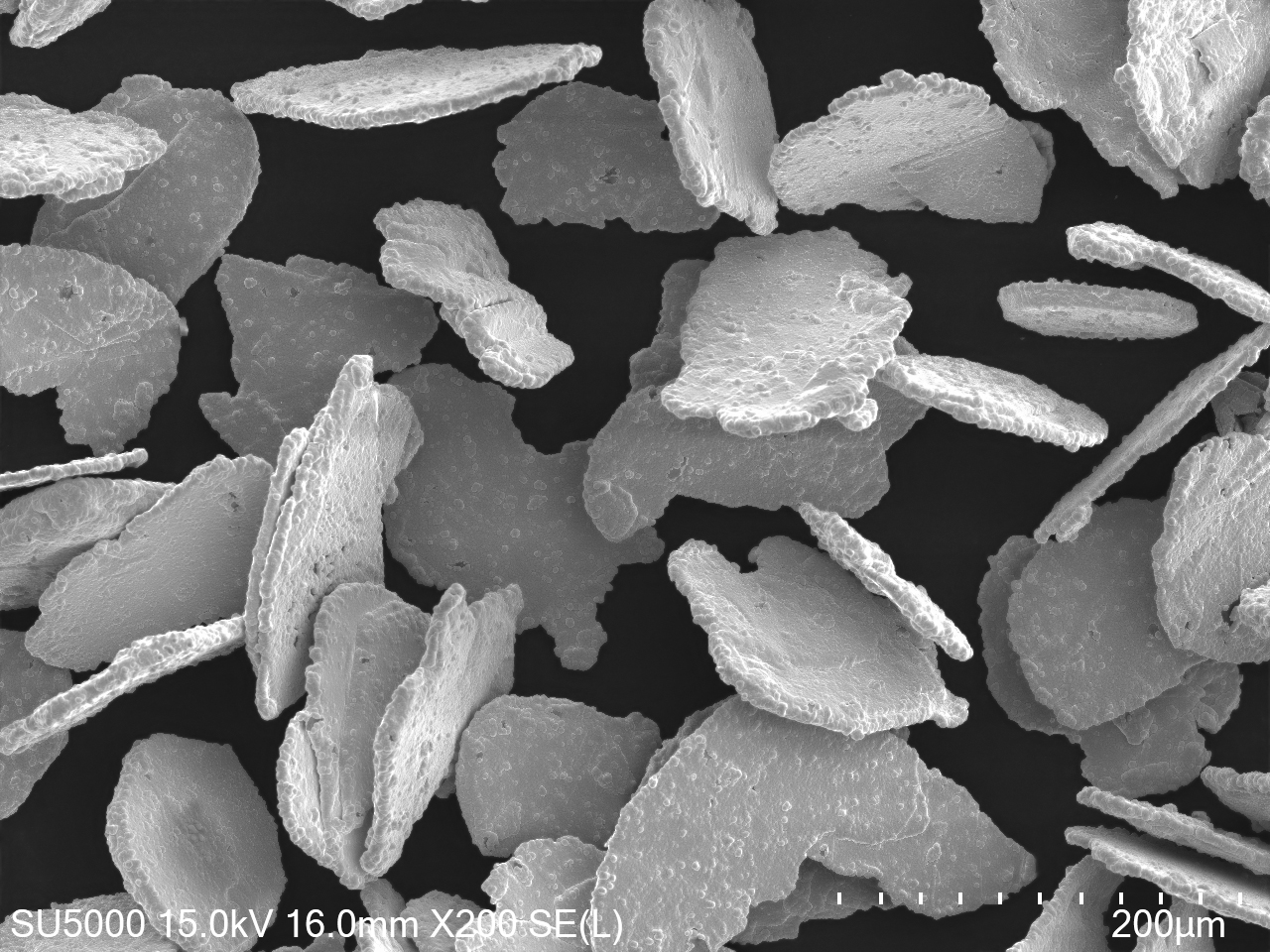

| KF-21T | Ni-Graphite 75/25 | 25 | Bal. | HRC 20 | ≤ 480ºC | •Murazvo, Max.kushanda tembiricha 480 ° C 1. Kupfeka zvinhu zve turbo compressor •Inoshanda kune nickel alloy uye zvikamu zvesimbi • Zvigadzirwa zvine girafu yepamusoro zvakakodzerwa netitanium zvikamu zvisina mupendero • High graphite content ichawedzera lubrication performance •Yakakwirira nickel yemukati inovandudza kusakukurwa kwevhu • Zvigadzirwa zvakafanana zvakasiyana nekuda kwekusiyana kweOEM | ||||||||

| KF-22T/R | Ni-Graphite 60/40 | 50 | Bal. | HRC 20 | ≤ 480ºC | |||||||||

| KF-21R | Ni-Graphite 75/25 | 25 | Bal. | HRC 20 | ≤ 480ºC | |||||||||

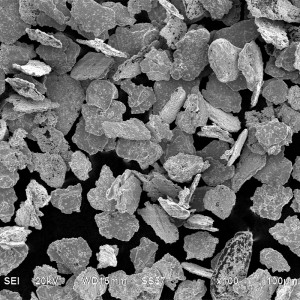

| KF-45 | Ni-Al2O3 77/23 | 23 | Bal. | HRC 40 | ≤ 800ºC | •Flame,APS, isingaite • Inogona kushandiswa kunyungudutsa crucible, terminal sealing surface uye mold pamusoro seyekudzivirira layer | ||||||||

| KF-56 | Ni-WC 16/84 | Bal. | 12 | HRC 62 | ≤ 400ºC | •Flame,APS, isingaite •Kusada kurohwa nesando, kukukurwa, kukwenya uye kutsemuka | ||||||||

| KF-50 | Ni-WC10/90 | Bal. | 10 | HRC 62 | ≤ 400ºC | •Murazvo, zvisina kujairika •Kusada kurohwa nesando, kukukurwa, kukwenya uye kutsemuka | ||||||||

| KF-91Fe | Fe-WC | 4 | 27 | 9.5 | Bal. | 5.5 | HRC 40 | ≤ 550ºC | •Flame, APS, zvisingaite, Max.tembiricha yekushandisa 815°C. •Pfeka mabatiro asingachinjike, ayo anogona kushandiswa kugadzirisa matangi mabhureki | |||||

| KF-110 | NiCr-Al 95/5 | 5 | 7.5 | Bal. | HRC 20 | ≤ 800ºC | •Murazvo, APS, Max.kushanda tembiricha 980°C. •Plasma spraying with self bonding | |||||||

| KF-113A | NiCrAl-CoY2O3 | Cr+Al:20, Ni+Co:75 | HRC 20 | ≤ 900ºC | •APS,HVOF, zvisingaite, Max.kushanda tembiricha 980°C. •Inoshanda pakugadziriswa kwepamusoro tembiricha bonding layer kana kupfeka / zvisina kurongeka zvikamu | |||||||||

| KF-133 | NiMoAl | 5 | 5 | Bal. | HRC 20 | ≤ 650ºC | •Self bonding, yakajairika hard coating yekutakura application •Zvakaoma, zvine ngura yakanaka kuramba uye nekukanganisa kuita •Inoshandiswa kune zvikamu zvemuchina, chigaro chekutakura uye valve | |||||||

| KF-31 | Ni-Diatomite 75/25 | •Flame,APS, zvisingaite, Max.kushanda tembiricha 650°C. •Pakuyeya chisimbiso chinobatika, zvinosanganisira zvinofambiswa zvisimbiso, grindable seal rings, low friction materials. | ||||||||||||