Self Fluxing Alloy ine kupfeka uye corrosion inodzivirira

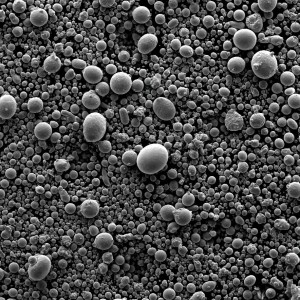

Tsanangudzo

NiCrBSi yakatevedzana alloy poda ine kuomarara kwepamusoro ndiyo inonyanya kushandiswa kupfeka kusagadzikana uye corrosion resistant alloy poda ine yakaderera kunyungudika uye hupfu hwekunyungudika tembiricha.Iyo ine yakanakisa self fusibility, wettability uye spray welding performance.Inowanzo shandiswa kurwisa corrosion uye kusapfeka, kunyanya kudzivirira uye kugadzirisa kweiyo inotsvedza kupfeka inodzivirira zvikamu.

Zvigadzirwa zvakafanana

| Brand | Product Name | AMPERIT | METCO/AMDRY | WOKA | PRAXAIR | PAC |

| KF-Ni15 | NiCrBSiFe | |||||

| KF-Ni25 | NiCrBSiFe | |||||

| KF-Ni35 | NiCrBSiFe | 12 | NI563 | 65 | ||

| KF-Ni45 | NiCrBSiFe | 14 | 69 | |||

| KF-Ni55 | NiCrBSiFe | |||||

| KF-Ni60B | NiCrBSiFe | |||||

| KF-Ni60A | NiCrBSiFe | 335 | 15 / 2001 | NI167 / 1275 | 60 | |

| KF-Ni60AA | NiCrBSiFe | 335 | 15 / 2001 | NI167 / 1275 | 60 | |

| KF-300A | Ni60+35WC-Ni | 36 / 734 | WC562 | 81 | ||

| KF-300B | Ni60A+50WC-Co | 34 / 734 | WC487 | 89 | ||

| KF-300C | Ni60+35WC-Co | |||||

| KF-300D | Self-fluxing Nikel base Tugsten Carbide |

Tsanangudzo

| Brand | Product Name | Chemistry (wt%) | Kuoma | Tembiricha | Properties & Application | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| C | Cr | Si | Fe | B | Ni | |||||

| KF-Ni15 | NiCrBSiFe | 0.15 | 5 | 2 | 5 | 1 | Bal. | HRC 15 | ≤ 700ºC | •Oxy-Acetylene, PTA, HVOF, APS, laser cladding, self-fluxing, spherical •Glass molds, mabearings •Kuoma kwakaderera, kusimba kwepamusoro •Good corrosion resistance and wetability |

| KF-Ni25 | NiCrBSiFe | 0.20 | 7 | 2.8 | 5 | 1.5 | Bal. | HRC25 | ≤ 700ºC | •Oxy-Acetylene, PTA, HVOF, APS, laser cladding, self-fluxing, spherical •Glass molds, mabearings •Kuoma kwakaderera, kusimba kwepamusoro •Good oxidation uye corrosion resistance pamwe nekunyorova •Exellent machinability |

| KF-Ni35 | NiCrBSiFe | 0.30 | 9 | 3 | 5 | 2 | Bal. | HRC 35 | ≤ 650ºC | •Glass molds, mabearings •Pistons • Zvigaro zvevharuvhu |

| KF-Ni45 | NiCrBSiFe | 0.45 | 13 | 3 | 10 | 2.5 | Bal. | HRC45 | ≤ 650ºC | •Glass molds, mabearings •Pistons • Zvigaro zvevharuvhu |

| KF-Ni55 | NiCrBSiFe | 0.75 | 15 | 3 | 10 | 3 | Bal. | HRC 55 | ≤ 650ºC | •Moulds •Bearings •Pistons |

| KF-Ni60B | NiCrBSiFe | 0.80 | 17 | 4 | 15 | 3.5 | Bal. | HRC60 | ≤ 650ºC | •Fani blades •Machubhu eboiler •Pistons |

| KF-Ni60A | NiCrBSiFe | 0.80 | 17 | 4 | 5 | 3.5 | Bal. | HRC 60 | ≤ 650ºC | •Oxy-Acetylene, PTA, HVOF, APS, laser cladding, self-fluxing, spherical •Mapiston, ma rollers, waya yekudhirowa mavhiri ekudhonza, extrusion screw •Kuoma kwepamusoro, kusakara uye kusaita ngura |

| KF-Ni60AA | NiCrBSiFe | 0.90 | 17 | 5 | 3 | 3.5 | Bal. | HRC60 | ≤ 650ºC | •Kubatanidza mafuta •Conveyor roller •Waya inodhonza mavhiri, •Extrusion sikuruu |

| KF-300A | Ni60A+35WC-Ni | Ni60A+35WC-Ni | HRC65 | ≤ 600ºC | •Oxy-Acetylene, PTA, HVOF, APS, laser cladding, self-fluxing, spherical •Waya yekudhirowa mavhiri, mashizha, pistons, impeller • Zvirinani kupfeka kuramba pane Ni60 | |||||

| KF-300B | Ni60A+50WC-Co | Ni60A+50WC-Co | HRC65 | ≤ 600ºC | •Chidhinha muchina •Sediment agitation •Extrusion sikuruu •Midziyo yekurima | |||||

| KF-300C | Ni60A+30WC-Co | Ni60A+30WC-Co | HRC65 | ≤ 600ºC | •Oxy-Acetylene, PTA, HVOF, APS, laser cladding, self-fluxing, spherical •Waya yekudhirowa mavhiri, mashizha, pistons, impeller • Zvirinani kupfeka kuramba pane Ni60 •Exellent particle uye yakaoma yakatarisana abrasion uye erosion resistance | |||||

| KF-300D | Self-fluxing Nikel base Tugsten Carbide | Proprietary | HRC65 | ≤ 600ºC | •Oxy-Acetylene, PTA, HVOF, APS, laser cladding, self-fluxing, spherical •Waya yekudhirowa mavhiri, mashizha, pistons, impeller • Zvirinani kupfeka kuramba pane Ni60 •Kuzvifambisa •Exellent particle abrasion uye kusagadzikana nekuora | |||||