Precious Metal Cr ine corrosion resistance

Tsanangudzo

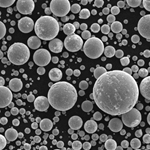

Chromium poda isimbi inoshandiswa zvakanyanya inowana mashandisirwo mumaindasitiri akasiyana.Inobudiswa nekuderedza chromium oxide nealuminium powder mumoto wepamusoro-soro, zvichiita kuti pave neupfu hwakatsetseka, hwakasvibira hupfu nekuchena kwepamusoro.

Chimwe chezvinhu zvinonyanya kuzivikanwa zvechromium poda ndeyekupokana kwayo kwegora.Inoshandiswa zvakanyanya mukugadzirwa kwesimbi isina tsvina uye yakakwirira-tembiricha alloys yeaerospace uye maindasitiri emotokari.Chromium's corrosion-resistant properties inobatsira kuwedzera kusimba uye hupenyu hwema alloys aya, zvichiita kuti ave akakodzera kushandiswa munzvimbo dzakaoma.

Kunze kwekushandiswa kwayo mukugadzirwa kwesimbi alloys, chromium poda inoshandiswawo sepigment mukugadzirwa kwependi, ingi, uye dhayi.Iyo yakanaka particle size yechromium poda inoita kuti ive sarudzo yakanaka yekugadzirwa kwemhando yepamusoro simbi inopera.Aya mapedzisiro anopa kugadzika, kusinga gara kuvirisa kupeta nekupenya kwakanyanya, zvichiita kuti ive yakakodzera kushandiswa mumhando dzakasiyana dzekushandisa, kusanganisira maindasitiri emotokari uye aerospace.

Chromium poda inoshandiswawo mukugadzira zvimwe zvinhu, senge nickel-chromium alloys, ayo anoshandiswa zvakanyanya mukugadzira zvinhu zvekudziya.Aya ma alloys akanakira kushandiswa mukupisa kwepamusoro-tembiricha, nekuda kwenzvimbo dzadzo dzekunyungudika uye kuramba kwecorrosion.

Muchidimbu, chromium poda chinhu chinogoneka uye chakanakisa corrosion resistance properties.Inoshandiswa zvakanyanya mukugadzirwa kwesimbi isina tsvina, yakakwirira-tembiricha alloys, uye simbi inopera.Zvimiro zvayo zvinoita kuti ive sarudzo yakanakira kushandiswa munzvimbo dzakaomarara uye nepamusoro-tembiricha maapplication, zvichiita kuti ive yakakurumbira zvinhu mumaindasitiri akasiyana.

Chemistry

| Element | Cr | O | |

|---|---|---|---|

| Misa (%) | Kuchena ≥99.9 | ≤0.1 | |

Pfuma yenyama

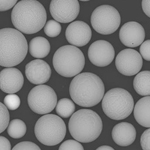

| PSD | Chiyero chekuyerera (sec/50g) | Kuwanda Kunooneka (g/cm3) | Sphericity | |

|---|---|---|---|---|

| 30-50 μm | ≤40s/50g | ≥2.2g/cm3 | ≥90% | |