Cobalt Base Alloy ine kusagadzikana kupfeka uye ngura

Tsanangudzo

KF-3321 ndeye cobalt-based alloy poda ine yakanakisa kupfeka kuramba uye yakakwirira-tembiricha oxidation kuramba.Inoumbwa necobalt, chromium, tungsten, nickel, silicon, uye kabhoni, uye inogonawo kunge iine zvidiki zvealuminium, niobium, tantalum, uye zvimwe zviwanikwa zvealloy.

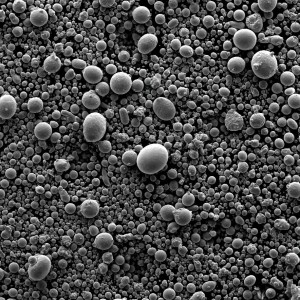

Powder Properties

Particle Size:KF-3321 ine particle size range re -140 kusvika +325 mesh, inoita kuti ive yakakodzera kune akasiyana maapplication panodiwa saizi yakanaka.

Type:KF-3321 igasi atomized powder, zvinoreva kuti inogadzirwa nekunyungudusa alloy uye nekuiisa atomizing ne-high-pressure gas.Izvi zvinoguma mune spherical hupfu chimiro, iyo inopa kuyerera kwakanaka uye kurongedza density.

Kuumbwa:KF-3321 icobalt-based alloy poda ine chikamu chepamusoro checobalt, iyo inopa yakanakisa kupfeka kuramba.Kuwedzerwa kwechromium uye tungsten kunowedzera kunatsiridza kupfeka kwayo kuramba uye yakakwirira-tembiricha oxidation kuramba.Nickel, silicon, uye kabhoni zvinopa imwe simba uye corrosion kuramba kune alloy.

Application

KF-3321 ivhu rinoshandiswa zvakasiyana-siyana rinogona kushandiswa mumaindasitiri akasiyana-siyana kune maapplication ayo anoda yakanakisa kupfeka kuramba uye yakakwirira-tembiricha oxidation kuramba.Mamwe maapplication akajairika anosanganisira:

High-temperature pressure valves:KF-3321's high-temperature oxidation resistance inoita kuti ive chinhu chakanakira kukwirisa-tembiricha mavharuvhu.

Akaona mazino:KF-3321's wear resistance and toughness inoita kuti ive yakakodzera kushandiswa mumazino esaha, ayo anoda zvinhu zvakaoma zvinokwanisa kumira kushushikana uye kuoma kwekucheka.

Extrusion screws:KF-3321's wear resistance and high-temperature oxidation resistance inoita kuti ive sarudzo yakanaka yekushandisa mune extrusion screws, iyo inoda zvinhu zvinokwanisa kumira kutonhora kwepamusoro uye kudzvinyirira kwe extrusion process.

Zvakafanana neSt12:KF-3321 ine zvivakwa zvakafanana kune St12, yakaderera kabhoni simbi inowanzoshandiswa muindasitiri yemotokari.Nekudaro, KF-3321 ine zvirinani kupfeka kuramba uye yakakwirira-tembiricha oxidation kuramba kupfuura St12, zvichiita kuti ive sarudzo yepamusoro yezvikumbiro zvinoda kukwirira kupfeka kuramba uye kugadzikana kwepamusoro-tembiricha.

Pakazere, KF-3321 ndeyepamusoro-inoshanda alloy poda inopa yakanakisa kupfeka kuramba uye yakakwirira-tembiricha oxidation kuramba.Zvimiro zvayo zvakasiyana-siyana zvinoita kuti zvive zvakakodzera kune zvakasiyana-siyana zvekushandisa mumaindasitiri akasiyana-siyana.

Zvigadzirwa zvakafanana

| Brand | Product Name | AMPERIT | METCO/AMDRY | WOKA | PRAXAIR | PAC |

| KF-331 | CoCrMoSi | 340 | 66 / 3002 | CO109 / 1247 | T400 | |

| KF-333 | CoCrMoSi | 342 | 68/3001/4800 | CO111 / 1248 | T800 | |

| KF-332 | CoCrWCNiSi | |||||

| KF-3321 | CoCrWCNiSi | |||||

| KF-3322 | CoCrWCNiSi | Zvakafanana ne344 | 4060 | CO106 1256 | 6 46 | |

| KF-3323 | CoCrWCNiSi | |||||

| KF-3324 | CoCrWCNiSi | 344 | 45 x40 | CO105 / CO285 | 90 | |

| KF-3325 | CoCrWCNiSi |

Tsanangudzo

| Brand | Product Name | Chemistry (wt%) | Kuoma | Tembiricha | Properties & Application | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cr | W | C | Ni | Si | B | Mo | Co | |||||

| KF-331 | CoCrMoSi | 8 | 2.6 | 28 | Bal. | HRC 54 | ≤ 840ºC | •Kuramba kupfeka, kuramba kukwenya •Corrosion resistance | ||||

| KF-333 | CoCrMoSi | 17.5 | 3.4 | 35 | Bal. | HRC53 | ≤ 840ºC | •Kuramba kupfeka, kuramba kukwenya •Corrosion resistance | ||||

| KF-332 | CoCrWCNiSi | 25 | 7.5 | 0.8 | 10 | 1 | Bal. | HRC 30 | ≤ 840ºC | •Chigaro chevhavha •Kubereka •Blade • Zvakafanana neSt1 | ||

| KF-3321 | CoCrWCNiSi | 30 | 4 | 1.5 | 3 | 1.4 | 4 | Bal. | HRC45 | ≤ 840ºC | • PTA, APS, HVOF, laser cladding, spherical • High tembiricha pressure mavharuvhu, akaona mazino, extrusion screws • Zvakafanana neSt12 | |

| KF-3322 | CoCrWCNiSi | 30 | 4.5 | 1 | 3 | 1.4 | Bal. | HRC 40 | ≤ 840ºC | • PTA, APS, HVOF, laser cladding, spherical • Injini mavharuvhu, yakakwirira tembiricha kumanikidza ukoshi, Turbo injini mashizha • Zvakafanana neSt6 •Good wear resistance mukupisa kwepamusoro | ||

| KF-3323 | CoCrWCNiSi | 28 | 0.25 | 3 | 1 | 5.5 | Bal. | HRC55 | ≤ 840ºC | •Turbine blades •Mavharuvhu emvura •Chigaro chevhavha | ||

| KF-3324 | CoCrWCNiSi | 25.5 | 7.5 | 0.5 | 10.5 | 1 | Bal. | HRC 30 | ≤ 840ºC | •Extrusion molds •Magetsi eturbine egasi | ||

| KF-3325 | CoCrWCNiSi | 21.0 | 5 | 0.1 | 1 | 1.6 | 2.4 | Bal. | HRC50 | ≤ 840ºC | • PTA, APS, HVOF, laser cladding, spherical • High tembiricha kupfeka kuramba •Mavharuvhu emudhudhudhu •Kuzvifambisa | |